INDUSTRY UPDATES

Thought leadership from the front lines of Industry 4.0.

Kurt Covine joins Invio Automation as CMO and Division President

We are excited to announce that Kurt Covine has joined Invio Automation as Chief Marketing Officer and Technologies Division President. Kurt brings 15+ years’ experience in sales and management, working [...]

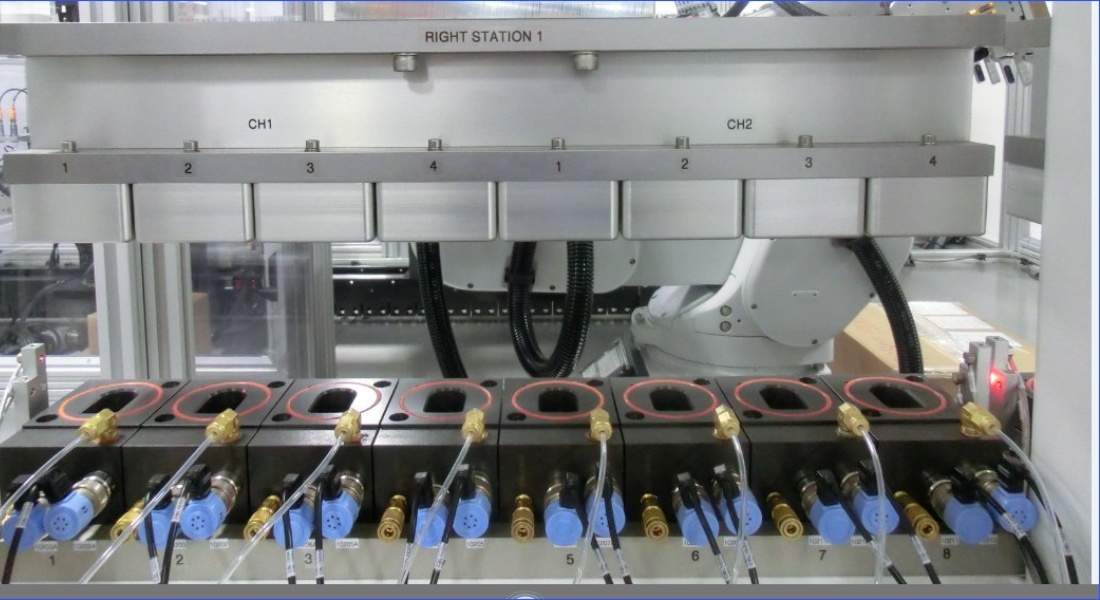

Minimizing Leaks through Technical Partnership: Invio Automation and Uson

Everything leaks. This is the unfortunate reality of any container carrying liquid or gas. The challenge is determining the acceptable leak rate of a given vessel and the magnitude of [...]

Welcoming Achilli Sfizzo as the new CEO of Invio Automation

We’re thrilled to welcome Achilli Sfizzo as the new CEO of Invio Automation! With a passion for innovation and a clear vision for growth, Achilli is excited to lead our [...]

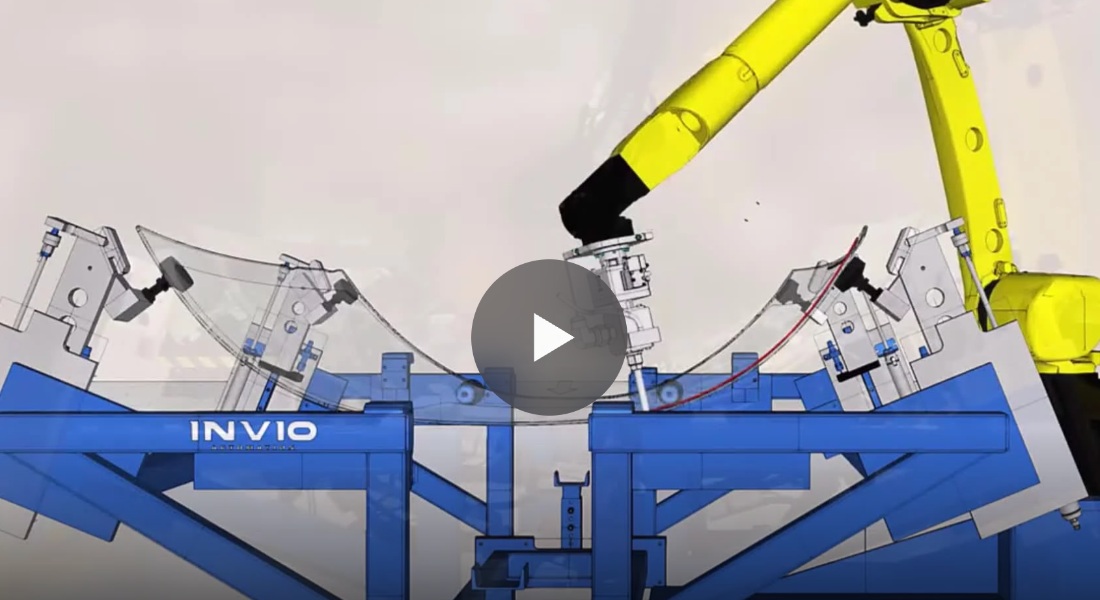

Factory of the Future: Robotic Dispensing

Automating dispensing applications is one of the best ways to enhance consistency, speed, and precision in manufacturing processes. Despite the technology's growth over the past decade—with advancements in intelligent sensors, [...]

Factory of the Future Consulting

When helping define an automation strategy with our manufacturing customers or scoping the projects already on their roadmap, our process at Invio Automation often begins with a factory of the [...]

Introducing the Future of Assembly: Our Innovative Platform Lift!

Say goodbye to the limitations of traditional assembly methods and hello to unparalleled efficiency and flexibility. Here's what makes our platform lift a game-changer: 360-Degree Assembly: With the ability to [...]

Speak to an Application Engineer today.

Speak with an engineer, set up a tour at one of our facilities, or start your project. We can quickly provide technical guidance and business case evaluation to help accelerate your automation exploration or provide actionable proposals if your requirements are known.