CAPABILITIESSmart Meters

Empowering smart meter manufacturers to scale confidently and consistently

From intricate components to sealed assemblies, Invio Automation meets your needs for custom automation solutions for smart meter manufacturing. We are your partner for fully custom systems built for your product cycle time and throughput goals. Trust us to streamline your smart meter production - from board to box.

What We Do:

High-precision, Small Parts Assembly

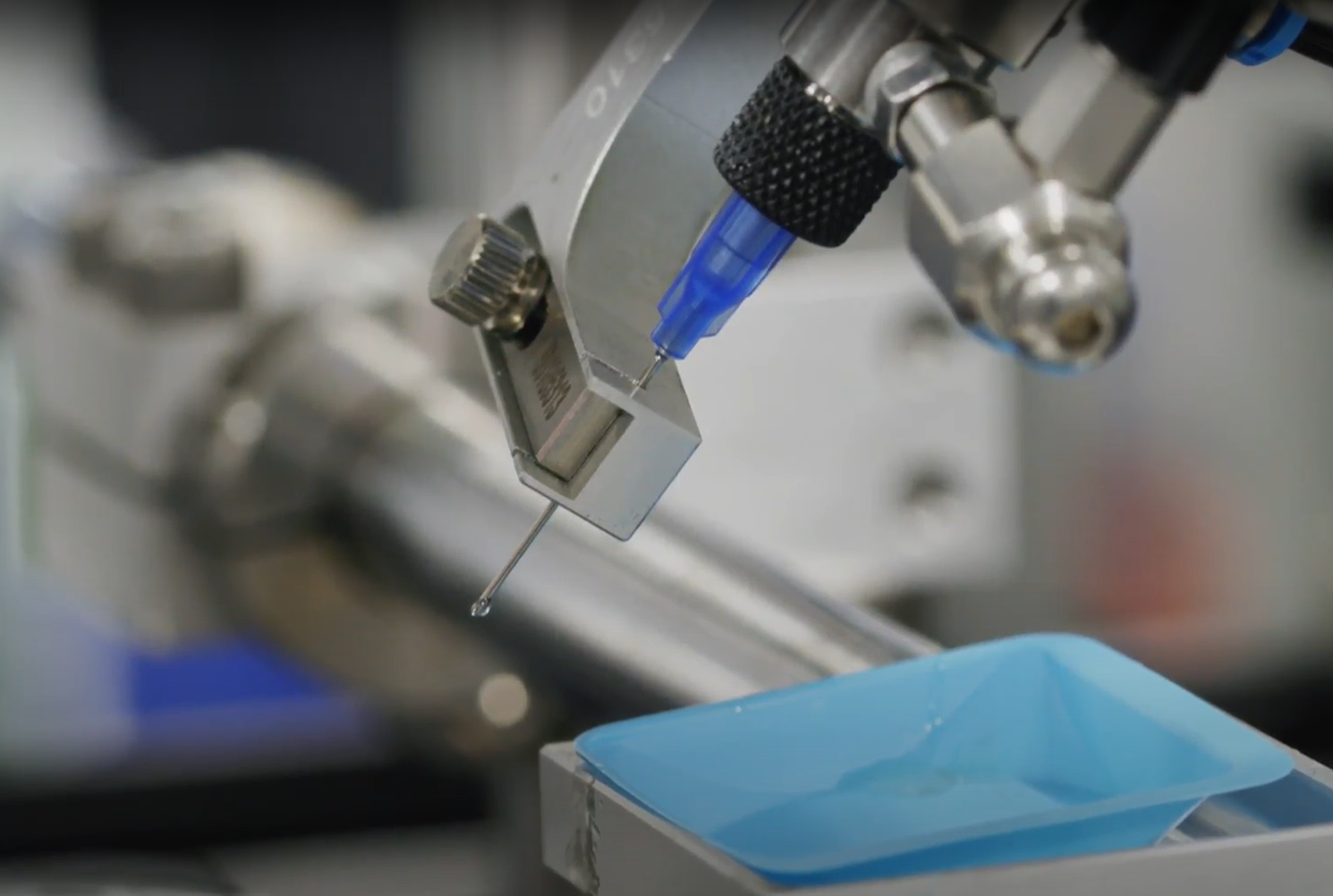

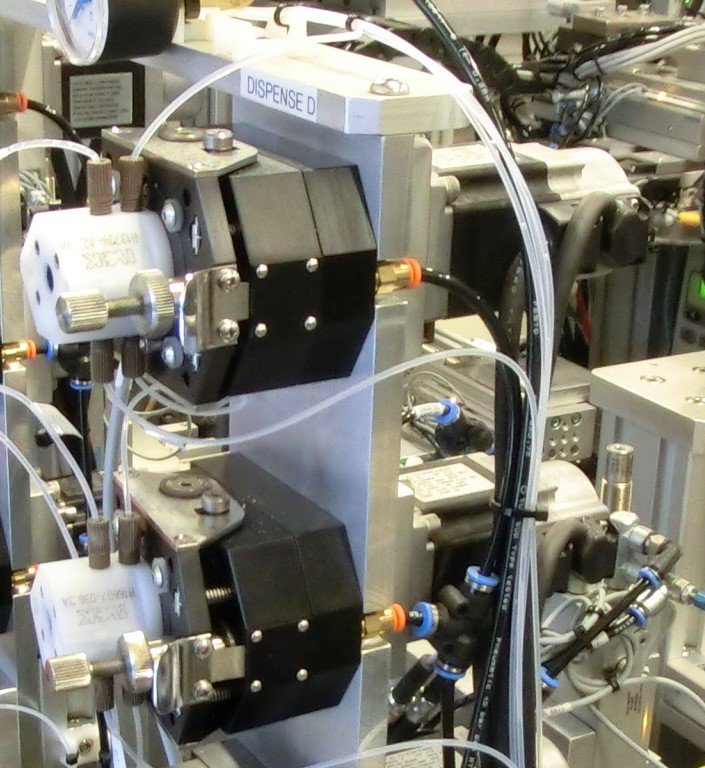

Dispensing & Potting of Adhesives

PCB Placement

Welding

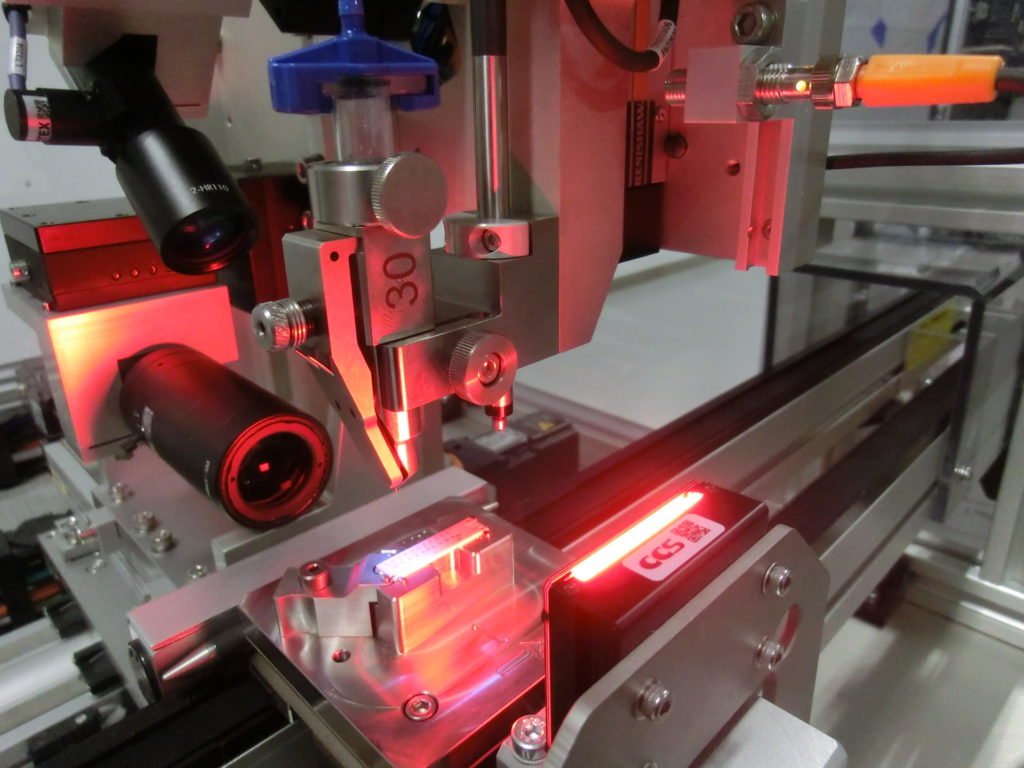

Vision Inspection

Leak Testing

Part Joining

High Speed Assembly

Why Invio for Automation of Smart Meter Manufacturing?

Assembly Automation Expertise

We understand that the manufacturing of smart meters comes with a unique set of challenges due to their complex functionality, demand for reliability, and the need to meet cost requirements.

We are experienced in the complex, multi-disciplinary assembly of mechanical, electrical, and electronic systems that your production line needs to handle.

Engineering Know-How

With more than 65 years of experience in industrial automation, we bring the know-how needed for high-precision placement and joining, with tight tolerances to ensure everything fits and functions perfectly.

Customizable & Scalable

Whether you're a high-mix, low-volume manufacturer or a high-volume producer, we offer flexible automation that can switch recipes quickly with minimal downtime.

Leverage Our Specialized Capabilities for Automation of Smart Meter Manufacturing

-

High speed, high accuracy feeding, picking and placement of small parts utilizing servo pick and place and robotics.

-

With decades of expertise in precision dispensing, we automate the potting process to shield PCBs and electronic components from moisture, vibration, and environmental stress.

-

PCB handling and placement systems that account for electrostatic protection, alignment, and insertion force, enabling accurate, repeatable placement even in high-speed, high-mix environments.

-

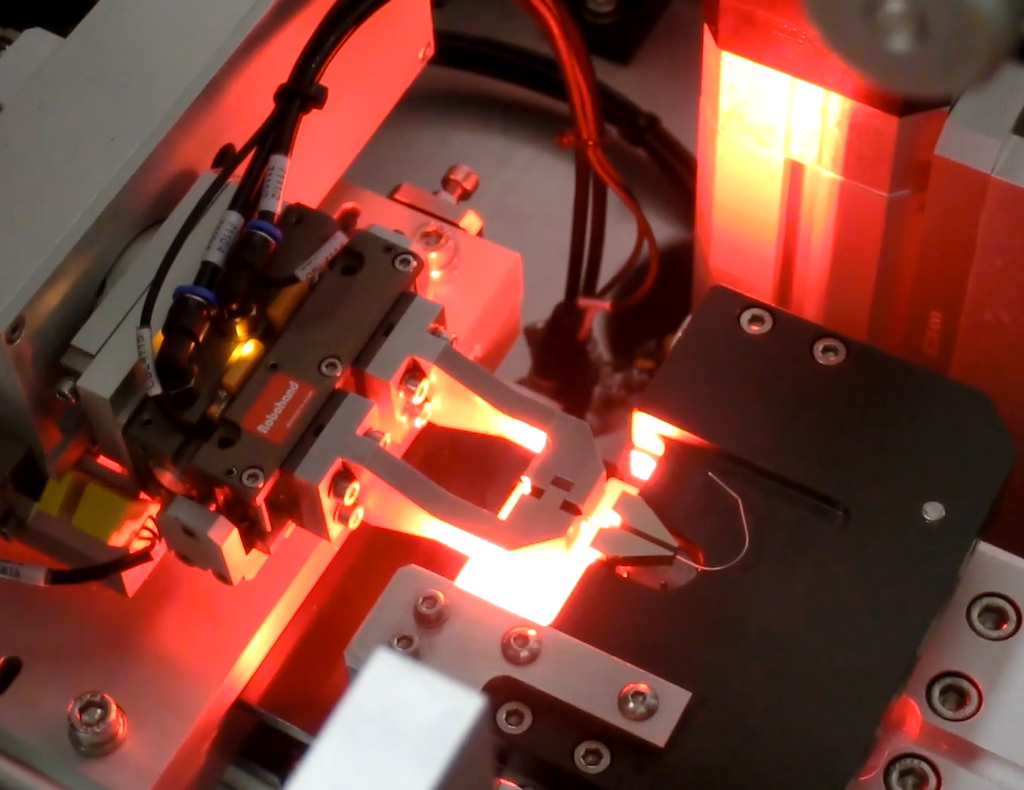

Precise amplitude, pressure, time, and energy control allow for repeatable, high-quality welds.

-

High-speed, high-resolution camera systems ensure 100% quality assurance by detecting even the dimensional, structural, and cosmetic defects.

-

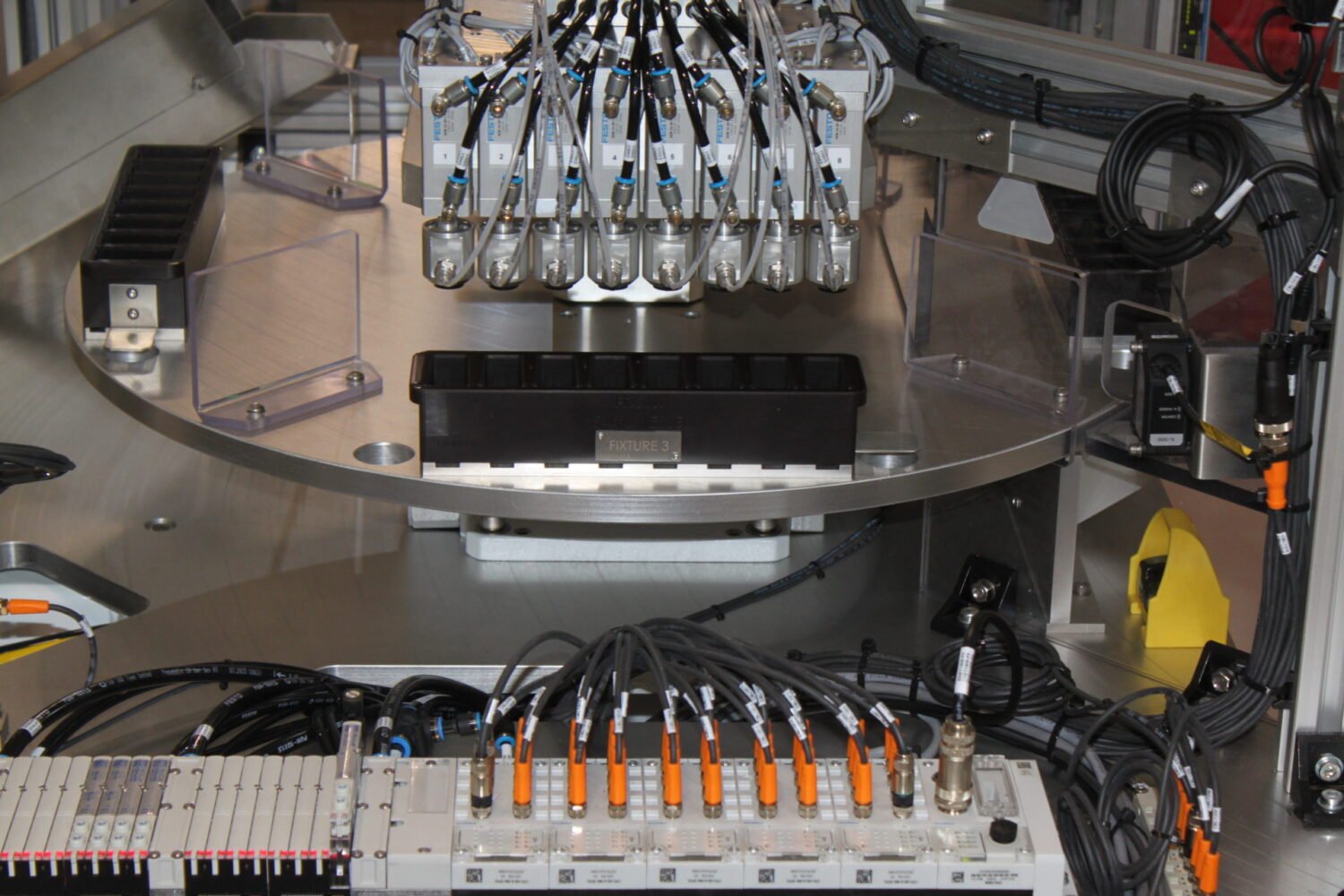

Automated leak testing solutions verify the seal integrity of your enclosures - critical for compliance with industry standards and long-term field reliability.

-

Laser welding and ultrasonic welding systems deliver robust, repeatable joints for housings, caps, and covers—ideal for plastic enclosures and hybrid materials.

Video Gallery

Dispensing and Potting: Precision Metered Dispense

Vision Inspection: Optical & Laser Profiler Inspection

Small Parts Assembly

Circuit Breakers and Switches

Leak Testing

A better tomorrow starts now.

Email us or fill out the form below to speak with an engineer, set up a tour at one of our facilities, or start your project.