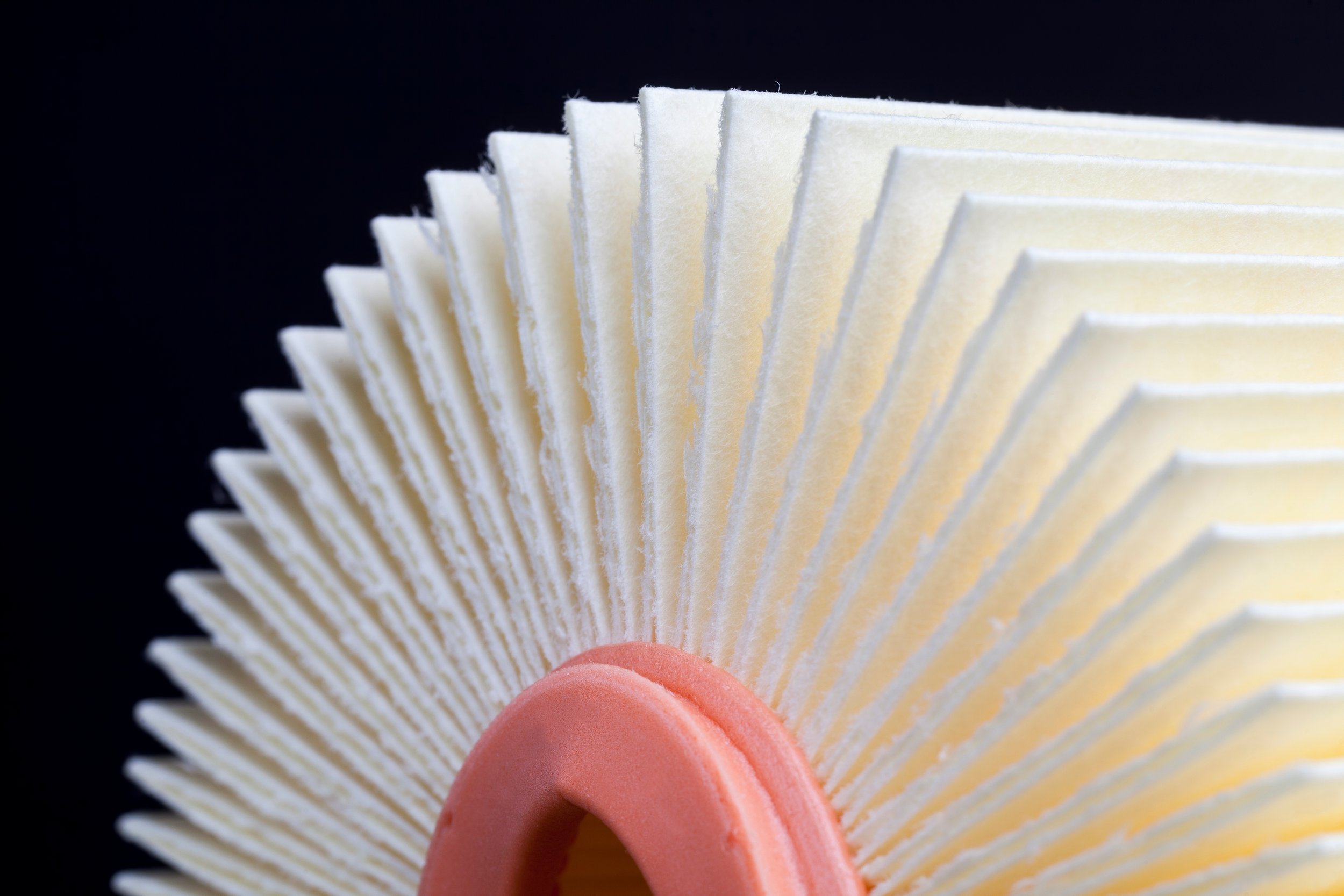

CAPABILITIESIndustrial Filters

Meeting your needs for high-efficiency filter assembly automation solutions

We specialize in the design, manufacturing, and integration of custom automation systems for high-efficiency filter production. Our solutions are engineered for precision assembly, repeatability, and maximum uptime—tailored to the needs of industrial filter manufacturers across HVAC, automotive, oil, gas, pharma, and clean air sectors.

What We Do

Filter Assembly

Stacking, pairing, bonding

Pleated filter assembly

Web handling, punching, and stacking of unique filter shapes

Preservation stands

Filter Testing

Membrane testing

Mechanical testing

Burst testing

Leak testing

Filter Packaging

Wet/dry packing

Spin dryers

End Capping

Welding and bonding

Curing and drying

Leak testing

Why Invio for Your Filter Production Automation System?

Industry-Specific Expertise

Advanced automation tailored specifically for industrial filter manufacturing

Fully Integrated Solutions

Seamless integration of end caps, mesh, and cores with robotic precision

Customizable & Scalable

Flexible solutions to increase uptime, increase throughput, or improve quality

Quality Assurance at Every Step

Processes to ensure we mitigate risk and ensure delivery on a consistent basis

Leverage Our Specialized Capabilities for Filter Assembly Automation

-

Clean, repeatable bonding for end caps, mesh, and center tubes. Precision control of amplitude, force, and time.

-

Integrated 6-axis and SCARA robots for filter core handling, orientation, and placement.

-

High-resolution camera systems for dimensional, structural, and cosmetic quality checks.

-

Volumetric or pressure/time systems with automated nozzle cleaning and flow sensors.

-

Measuring appropriate flow rates through product filter under controlled conditions as well as checking for occlusions in fluid paths.

-

Chemical conditioning of filters for cleanliness and decontamination prior to clean packaging and shipment.

-

Modular conveyors, automated boxing, labeling, and serialization systems for finished products.

Case Studies: Explore Our Expertise

-

The Challenge: Design automated system to produce specialty filters that could handle very sensitive membrane for pharmaceutical manufacturer

The Solution: Designed a three-stage system for processing membrane that included a slitter, a converter, and a stacker assembly machine - incorporating servo positioning and zero clearance shear cutting

Key Capabilities: Membrane Handling, Zero Clearance Punching, Precise Heat Sealing, Precision Torquing, Ultrasonic Welding

-

The Challenge: Develop hybrid system for assembling sterile laboratory media filters

The Solution: Designed highly customizable system that used a unique method for building dies to achieve zero clearance to provide clean membrane punching

Key Capabilities: Precision Assembly, Punch and Die, Membrane Handling, Web Handling, Servo Positioning, Shear Cutting

Video Gallery

Precision automation to manufacture specialty filters for use in pharma & microchip fabrication

Fully integrated thermal bonder automation for use in plastic part welding

Preservation System

A better tomorrow starts now.

Email us or fill out the form below to speak with an engineer, set up a tour at one of our facilities, or start your project.