Case Studies

Medical Device & Life Sciences

Browse our collection of case studies. Our experience is ever-evolving, so please check back soon for new case studies. If you’re interested in more details on any of our projects, please contact us.

Catheters

The Challenge:

Create an automated process for threading a minuscule diameter tube onto another small tube to create a cannula assembly.

The Solution:

Designed a solution that involved a proprietary method of threading tubes and precise control of heat to bond tubes together.

Drug Delivery

The Challenge:

Transition process for precision dispensing of a high-viscosity, silicone-based drug from clinical trial state to production state.

The Solution:

Built an automated drug delivery system that met full pharmaceutical cleanliness standards.

Diagnostics

The Challenge:

Design an automated system reagent filling system for a diagnostic testing device that incorporates unique product bar codes.

The Solution:

Designed an automated system that filled each vessel with 3 different reagents at a rate of 40 packs per minute.

Inhalers

The Challenge:

Replace the manual system with an automated system that feeds and assembles 9 components into the device.

The Solution:

Designed a robust system that lasted 26 years, only decommissioned when the cost of obsolete parts was more than the cost of a rebuild.

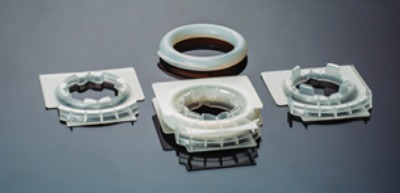

Diagnostics

The Challenge:

Meet the urgent pandemic need for an automated assembly system to manufacture PCR test base devices at 150 ppm.

The Solution:

Delivered an assembly system that would normally take 52 weeks in half that time.

Injectors

The Challenge:

Automate the process of assembling high-volume disposables with numerous SKUs and product versions.

The Solution:

Built a system with a series of pick and place stations to assemble epi injectors, in line with GAMP guidelines.

Injectors

The Challenge:

Design and build an economical needle-bending machine.

The Solution:

Developed a system of modules that each produced a bent needle every 8 seconds and saved customers millions in equipment costs and a long changeover time.

Inhalers

The Challenge:

Design and build a fully FDA-validated, automated system to assemble, test, and qualify a next-generation inhaler device.

The Solution:

Developed a proprietary force-distance profiling station and validated the system to the highest FDA GAMP level.

Speak to an Application Engineer today.

Speak with an engineer, set up a tour at one of our facilities, or start your project. We can quickly provide technical guidance and business case evaluation to help accelerate your automation exploration or provide actionable proposals if your requirements are known.