CAPABILITIESAutomated Guided Vehicles (AGVs)

Standard & custom automated guided vehicles & autonomous guided vehicles (AGVs) for high payload & heavyweight applications

Speak to an Application Engineer

Connect with an Invio engineer at any point in your project process. We can quickly provide pricing and technical guidance to help accelerate your AGV exploration or provide actionable proposals if your requirements are known.

Our line of high payload and high capacity AGVs help companies manufacture:

Solar Panels & Photovoltaic Cells

Wind Turbines

Battery Packs

Switches, Inverters, & Power Transmission Equipment

Cars

Vans

EV Skateboards

Tractors, Combines, Seeders

ATVs

Skid Steers

Telehandlers

Semi-trucks

Defense Equipment

Engines & Thrusters

Turnkey Fabrication & Assembly Lines that Utilize AGVs

Optimize your manufacturing strategy with flexible, responsive AGV assembly lines. No longer constrained by traditional in-floor, fixed-conveyance systems that act as permanent monuments, you can experience production rate increases, model mix shifts, and product design changes. System initializations and reconfigurations take a fraction of the time and expense of fixed-conveyance systems and require none of the permanent monuments or heavy construction on the plant floor.

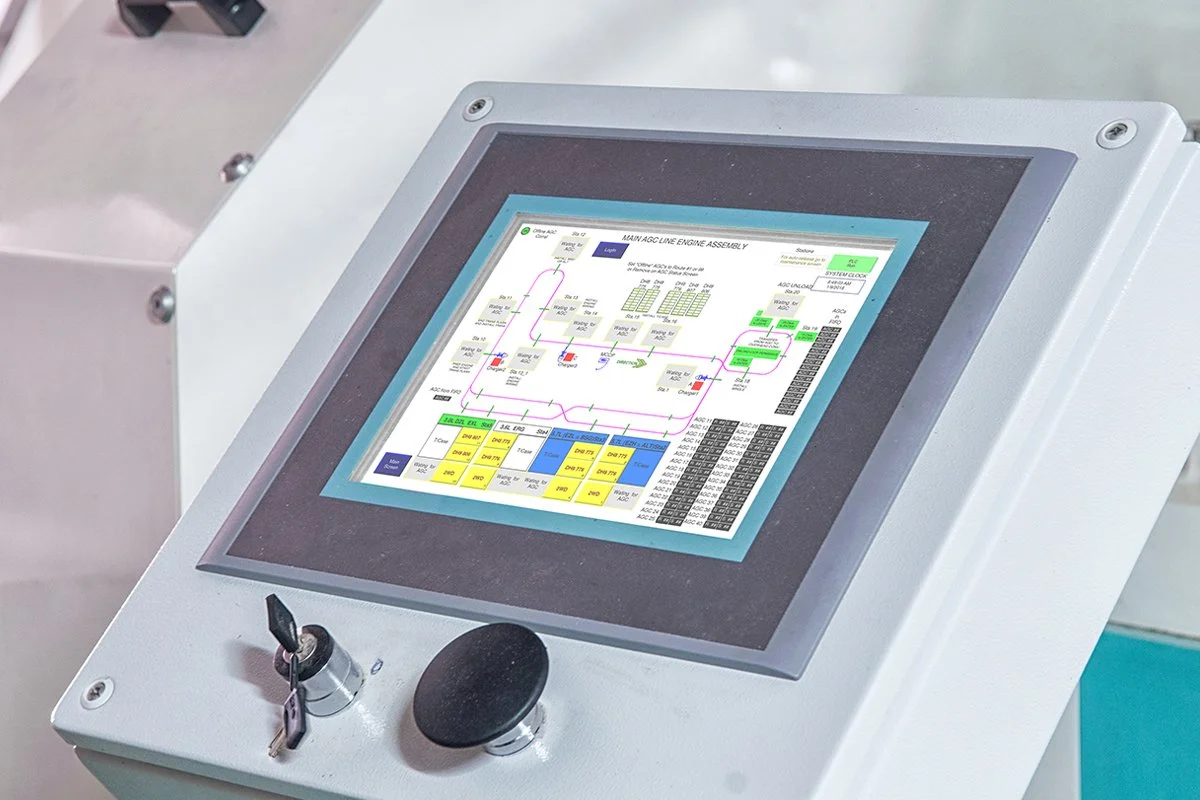

We provide up-level MES and SCADA systems via Ignition to connect assembly line tooling like lift assists, torque and secure tools, cameras, and badge swipe integration to advance product only when quality and process steps are complete.

Our navigation options include a tapeless SLAM LIDAR approach as well as lower cost in-floor media.

AMRsA long term track record of scale & custom development

5 Million

40,000

1999

62

our first AGV deployment into the Fortune 500 environment

team members dedicated to support and service

pounds is the heaviest load we’ve transported in a production environment

annual uptime hours of our AMR & AGV fleets across all of our customers

Natural Feature Navigation Powered by Bluebotics™

What are our navigation options? Invio AMRs & AGVs utilize a variety of navigation methods including a LIDAR-based natural feature navigation from our technology partner, Bluebotics.

Quick and easy path modification

Mission design

Software-driven fleet scaling

Accurate to ±1 cm

Factory dashboards and analytics including OEE, activity hotspots, & dwell time

We also offer tape-based, magnetic bar, and other navigation alternatives that might serve your operation better. Our application engineers can offer guidance on the cost- and environment-optimal navigation approach.

High Capacity Standard Products & Launch Points for Custom Development

We offer both standard products as well as highly custom AGVs and AMRs. We seek applications at higher payloads and routinely convey and transport products that are 10,000lbs, 20,000lbs, 30,000lbs, and up. All of the product fixturing and dockable transport carts are designed and manufactured in-house. Our AGVs are frequently paired with scissors lifts, powered trunnions, manual and automated slide tooling, dunnage compartments, and additional safety sensors to survey and check obstructions in all planes.

ModelHW25000

Our heaviest standard product has been used by semi-truck manufacturers to transport chassis through the assembly line. A skid steer OEM customized the HW25000 to increase material velocity within their highly automated weld processes. A MES system coordinated and reset product fixturing on-deck.

On-deck Load Capacity: 25,000 lbs (11,340 kg)

Towing Load Capacity: 25,000 lbs (11,340 kg)

Maneuverability: Forward / Reverse / Rotate

ModelDTD10000

Enhance safety and increase productivity in your facility by reducing dependence on traditional fork trucks and tuggers. The DTD10000 is favored in rugged, heavy industrial environments where transporting heavy products is dangerous and inefficient. In production at Bobcat, John Deere, Peterbilt, and First Solar

On-deck Load Capacity: 10,000 lbs (4,536 kg)

Towing Load Capacity: 10,000 lbs (4,536 kg)

Maneuverability: Forward / Reverse / Rotate

ModelTD5000

A popular mid-capacity model suited for assembly lines for rec sports (John Deere), small vehicles, marine engine assembly (CAT) or agriculture drivetrain applications (John Deere). As an option, there’s ample on-board power to drive hydraulic lift motors with operator controls and toggles.

On-deck Load Capacity: 3,500 lbs (1,588 kg)

Towing Load Capacity: 5,000 lbs (2,268 kg)

Maneuverability: Forward / Reverse / Rotate

ModelE3500

A model highly popular with Invio’s mobility customers. The E3500 is a great AGV for transporting sub-assemblies, WIP, and finished goods through highly automated and operator heavy processes. Best-in-class safety and power management.

On-deck Load Capacity: 1,000 lbs (454 kg)

Towing Load Capacity: 3,500 lbs (1,588 kg)

Maneuverability: Forward

ModelLD1500

The LD1500 is Invio’s light duty standard product used for transporting components and assemblies to point of use on the assembly line. In production at Airbus, Magna, Honda, Ford, Whirlpool, Trane, Cummins, Volvo, JLG, John Deere, Marvin Windows, and Mack Trucks.

On-deck Load Capacity: 500 lbs (227 kg)

Towing Load Capacity: 1,500 lbs (680 kg)

Maneuverability: Forward / Reverse

Eliminate fixed conveyance and fork truck traffic for your assembly line with Invio’s AMR & AGV product lines. We optimize uptime with industry standard components and a flexible architecture and eliminate the use of black box software and unproven technologies. Instead, we utilize best-in-class components like Allen-Bradley and Siemens PLCs and Bluebotics Natural Feature Navigation.

Common AGV Accessories, Peripherals, & System Components

Intellicharger for intra-process charging. Underside and inductive options available.

Companion Frames, Custom Dollies, Dunnage Interfaces, & Build Surfaces & Skillets

Ignition MES / SCADA for factory dashboards and intelligence. Full integration to existing & legacy systems.

AGV & AMR Robotic Process Integration. Certified Kuka, Fanuc, Yaskawa, & UR Integrator

Master Control Panels for PLC-based Integration to other equipment and systems

Integrated Lifts, Lazy Susans, & Powered Trunnions to re-orient product for assembly line workers

Lean Material Handling and Supermarkets

Reduce your line-side footprint and deliver material reliably with AMRs & AGVs. AMR & AGV data analytics allow you to optimize fleet sizes and line-side delivery schedules based on fluctuating customer demand.

Our AMRs & AGVs provide a turn-key solution for the factory-level integration of custom companion frame tooling, gravity flow racks, powered roll conveyors, and kit carriers. These seamless system components enable your AGV fleet to deliver material wherever you need, be it warehouses, cross-docks, receiving dock-to-stock, stock-to-point of use, supermarkets or line-side delivery.

Ignition Dashboards & FlexSim Simulations

Test drive your factory layout and operational processes before breaking ground. Our layout and process engineers work with customers to validate throughput expectations, identify bottlenecks and evaluate how layout alternatives drive efficiencies. We also build business cases by providing simulations that will help you obtain support from senior management.

AGV Reference Videos

Product rotation trunnion for EV battery assembly

The heavyweight assembly environment is our sweet spot

Trunnion equipped AMR for production line automation

Reorient product throughout your process to improve operator access and ergonomics

Interface Invio lift assists & assembly tooling with heavy payload AGVs

Optimize operator ergonomics

Significantly more application videos can be found on our YouTube Page here

Height adjustable flexible conveyance for ATVs and Rec Sports OEMs

Reorient product throughout your process

Speak to an Application Engineer

Connect with an Invio engineer at any point in your project process. We can quickly provide pricing and technical guidance to help accelerate your AGV exploration or provide actionable proposals if your requirements are known.

Our line of high payload and high capacity AGVs help companies manufacture:

Solar Panels & Photovoltaic Cells

Wind Turbines

Battery Packs

Switches, Inverters, & Power Transmission Equipment

Cars

Vans

EV Skateboards

Tractors, Combines, Seeders

ATVs

Skid Steers

Telehandlers

Semi-trucks

Defense Equipment

Engines & Thrusters

Recent Blog Posts